What do you guy's reccomend?

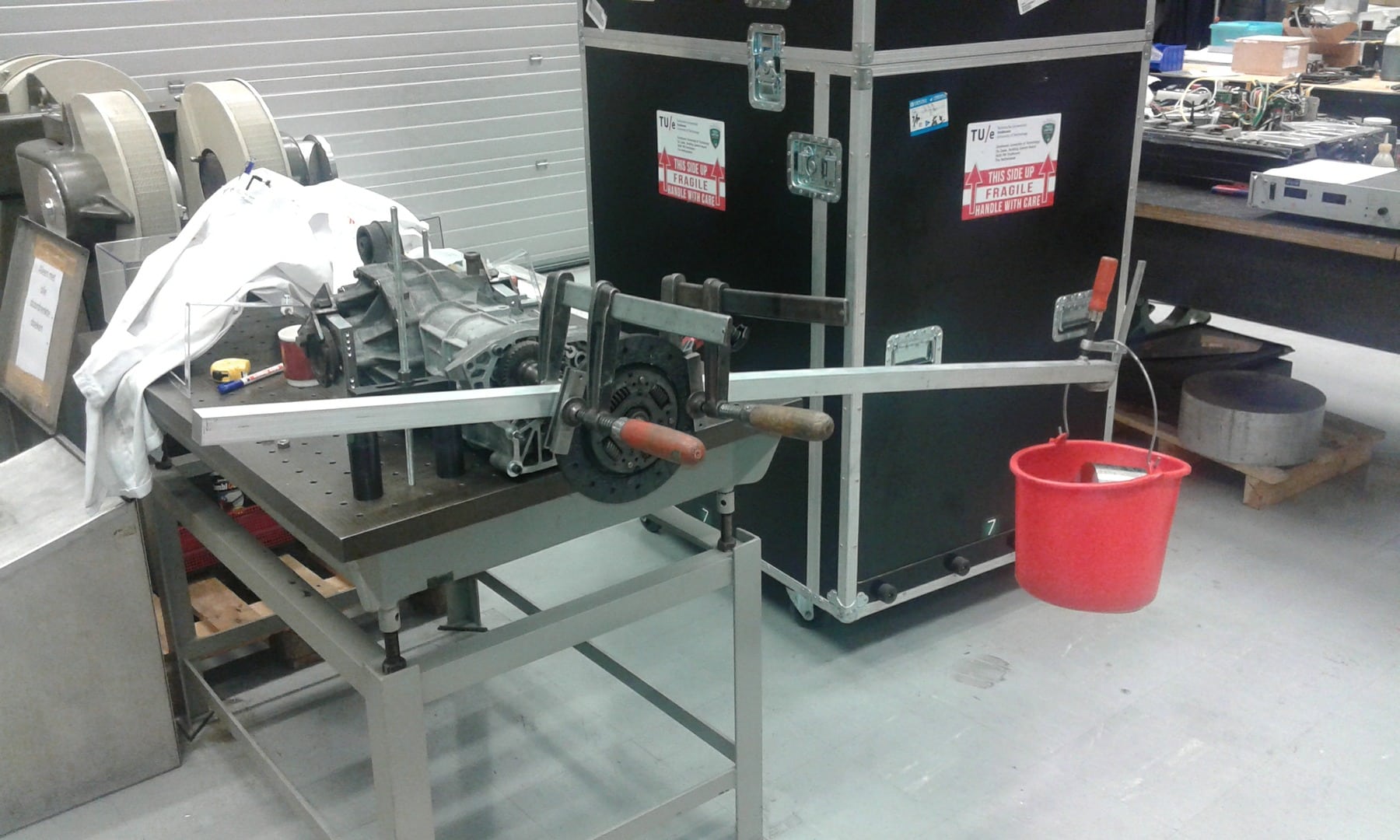

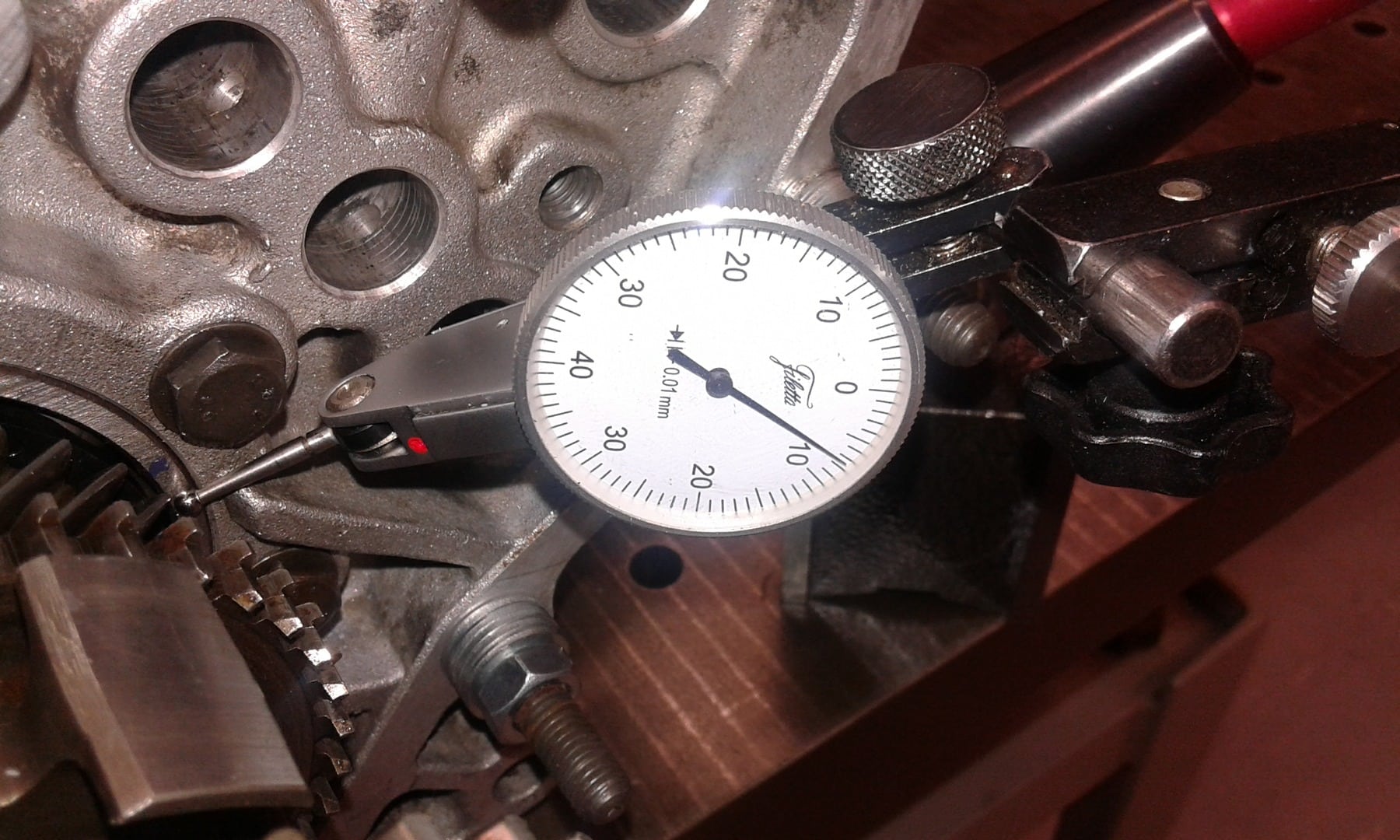

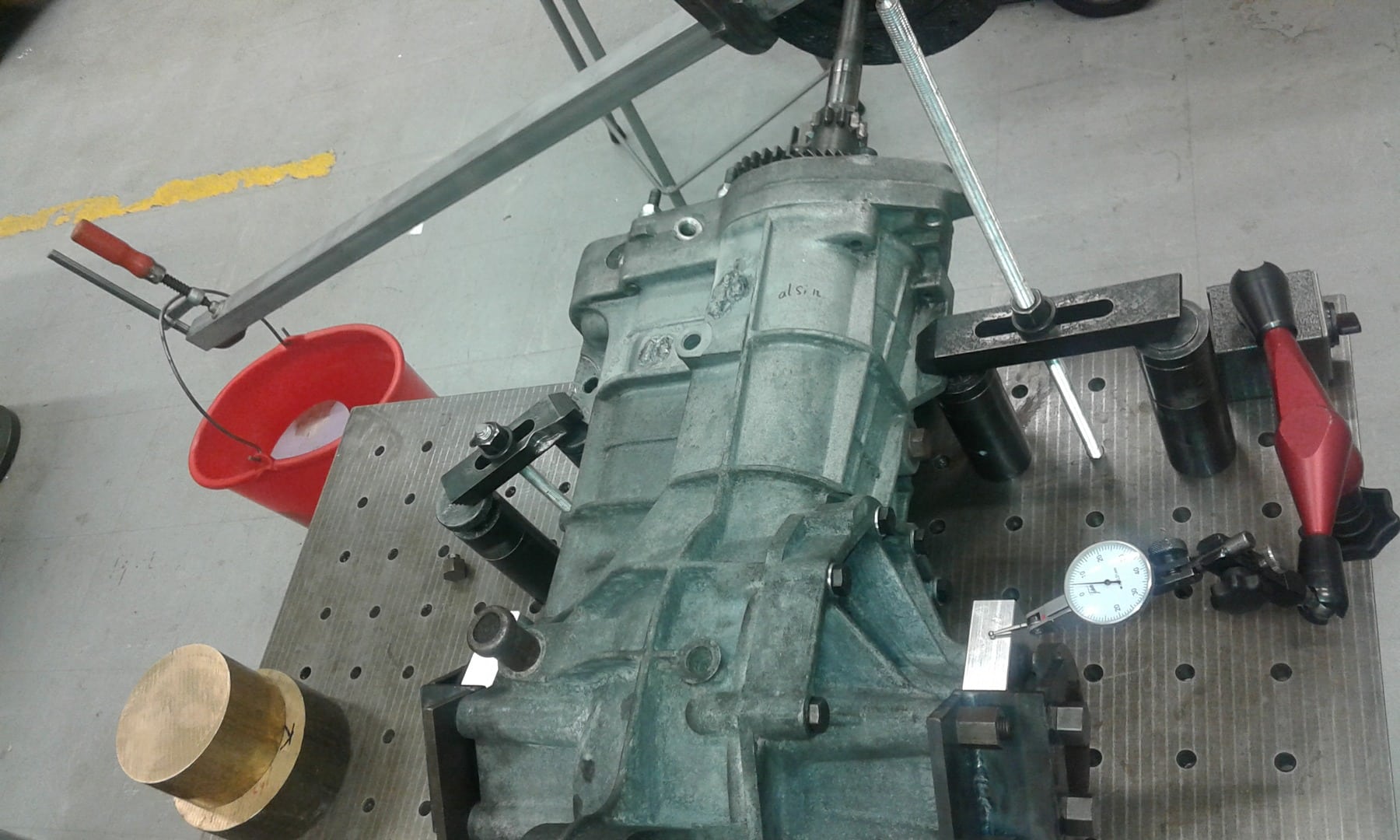

I already started with the middle bearing plate. It's gonna be milled from a 7075t6 aluminium. I don't know the axial load forces axact but aplying a 500 kg load disorted it 0.04mm. 1000kg 0.08 and 1500kg 0.12mm.nice linear. Also i saw it already was bent a bit in load direction. 0.015mm that could be machine error but i think its a lot

Maybe i'll make a batch.

-Also adding housing stiffnes would be nice i guess. Welding up aluminium or a steel brace style one...?

-And maybe a thicker inlet axle because i heard they fail sometimes...?also an other clutch plate becuase of enlarged clutch spline

-Then the brace for the clutchhousing

This all to give it some a little bit more strenght.